Kevlar Para Aramid

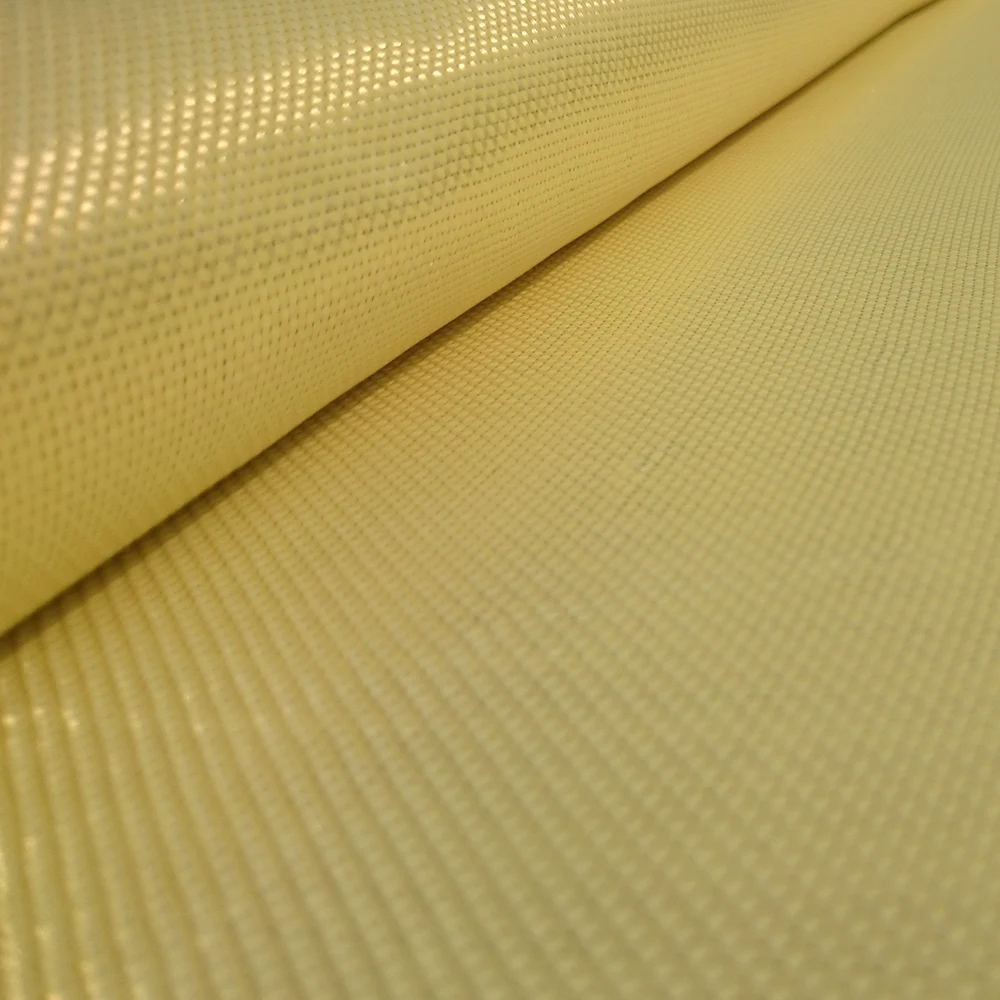

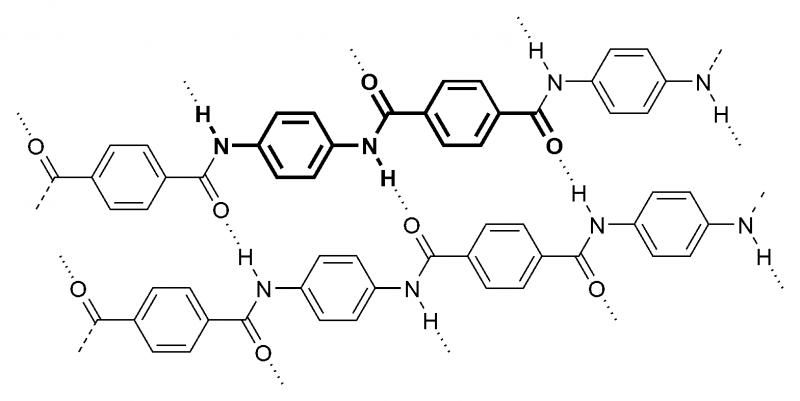

Kevlar para aramid is an aromatic polyamide that is characterized by long rigid crystalline polymer chains.

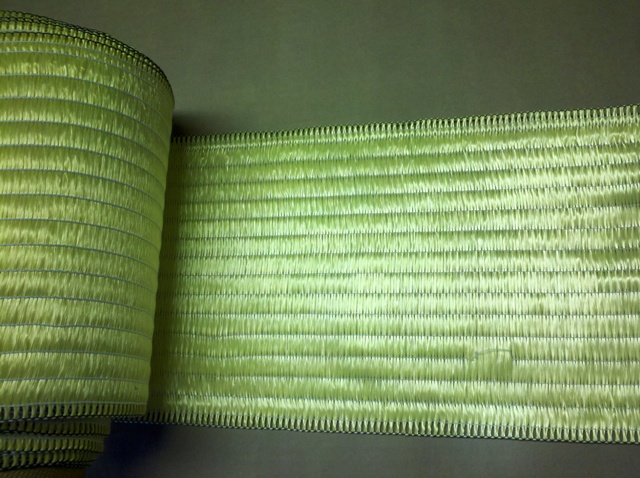

Kevlar para aramid. Created by stephanie kwolek dupont kevlar is a heat resistant para aramid synthetic fiber with a molecular structure of many inter chain bonds that make kevlar incredibly strong. Kevlar para aramid version 2 0 revision date 05 28 2015 ref. 150000002634 2 9 hazardous warnings. Para aramid fibers such as kevlar and twaron which are slightly different have outstanding strength to weight properties and have high tenacity which makes it difficult to cut or fray.

Not required other hazards the hazards of this product are associated mainly with its processing prolonged inhalation of respirable dust. Kevlar para aramid why kevlar para aramid. These fibers are created by the the dry jet wet spinning method resulting in a fiber which consists of fully extended. At the point of creation para aramid fibers have a strength of around 2 03 2 06 n tex.

To this day it is known for its strength. Para refers to the specific linkage position of the aromatic rings. History kevlar was first developed by chemist stephanie kwolek at dupont in the 1930 s. Kevlar para aramid fiber empty kevlar aramid fiber introduced commercially by e.

Yang 1993 bunsell 1975 reported that kevlar 49 fibers fibrillated but did not fail unless the maximum applied load was greater than 80 of the tensile strength. Molecular structure chemical name poly para phenylene terephthalamide. Kevlar para aramid materials was introduced on a commercial scale as ppe in the 1960s and 70s. Hazardous prevention measures.

Best known for its use in ballistic body armor kevlar also has many other applications because of its high tensile strength to weight ratio. Para aramid fibers possess outstanding resistance to cyclic loading conditions fig. Longitudinal alignment of the hydrogen bonds enables high tensile strength and modulus. 17 25 in particular kevlar and technora have a fatigue resistance which some claim is better than carbon fibers.

May form combustible dust concentrations in air. Kevlar features not only excellent strength and high modulus but also outstanding resistance to impact and heat. Para aramids such as kevlar and lower cost alternatives display high tensile strength the maximum stress that a material can withstand and modulus behavior the tendency of a material to deform when force is applied. It was first commercially used in the 1970 s as a replacement for steel in racing tires.