Para Aramid

Longitudinal alignment of the hydrogen bonds enables high tensile strength and modulus.

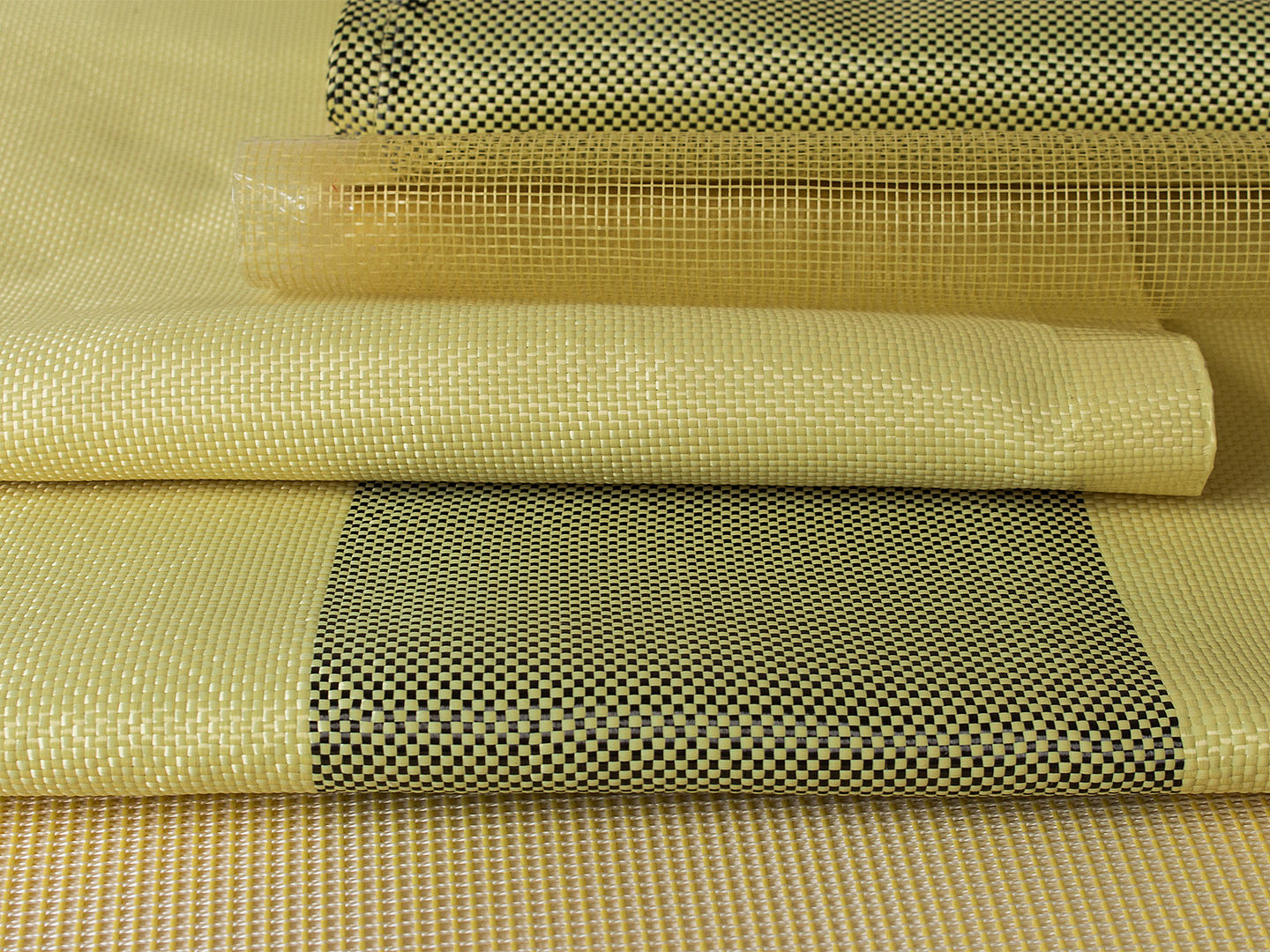

Para aramid. Para aramid is called one of the three high performance fibers in the world with carbon fiber and high density high modulus polyethylene hdpe as the other two. So what are the differences between meta aramid and para aramid yarns. Para aramid is a synthetic fiber that is used in the manufacture of safety gloves and other safety equipment. Teijin s new aramid fiber fabri.

The chain molecules in the fibers are highly oriented along the fiber axis. The full name is poly p phenylene terephthalamide abbreviated as ppta or aramid. Kevlar para aramid not just. As rope it has high strength temperature difference 40 c 500 c insulation corrosion resistant performance low elongation advantages.

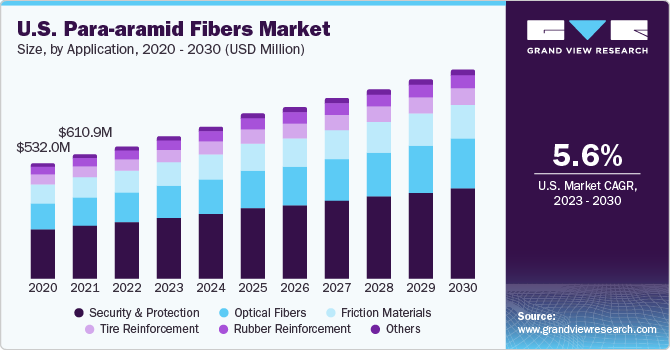

About para aramid para aramid belongs to the aromatic polyamide family. Para aramid gloves resist abrasion but the primary motivation for using the fiber is its strong heat resistance. Para refers to the specific linkage position of the aromatic rings. During 2010 14 with multiple para aramid fiber projects being put into production para aramid fiber output in china witnessed soaring growth and hit about 1 3 ktons in 2014 as it is predicted lifting the country s self sufficiency rate.

Twaron a brand name of teijin aramid is a para aramid it is a heat resistant and strong synthetic fibre developed in the early 1970s by the dutch company akzo nobel s division enka bv later akzo industrial fibers the research name of the para aramid fibre was originally fiber x but it was soon called arenka although the dutch para aramid fiber was developed only a little later than dupont. Para aramid fibers possess a superior potency five times more formidable when compared with steel modest loss of durability through prolonged abrasion stretching and flexing. Kevlar para aramid is an aromatic polyamide that is characterized by long rigid crystalline polymer chains. Aramid fibers are a class of heat resistant and strong synthetic fibers they are used in aerospace and military applications for ballistic rated body armor fabric and ballistic composites in marine cordage marine hull reinforcement and as an asbestos substitute.

It possesses a superb dimensional resistance. The result is a semi crystalline fiber with its molecular chain. Para aramid fiber industry in china developed late and progressively achieved industrialization in 2010. Fiber line enhancing processes for kevlar.

This fiber offers not just exceptional intensity and high modulus but at the same time the superior level of resistance to. The name is a portmanteau of aromatic polyamide.